In a broad sense, diesel and gasoline engines are comparable. Both are examples of internal combustion engines (ICEs), which were designed with the goal of transforming the chemical energy in fuel into mechanical energy. The engine’s cylinders’ pistons oscillate up and down thanks to the mechanical energy. They are joined by connecting rods to a crankshaft. They move in such a way as to produce the rotating motion required to advance the vehicle.

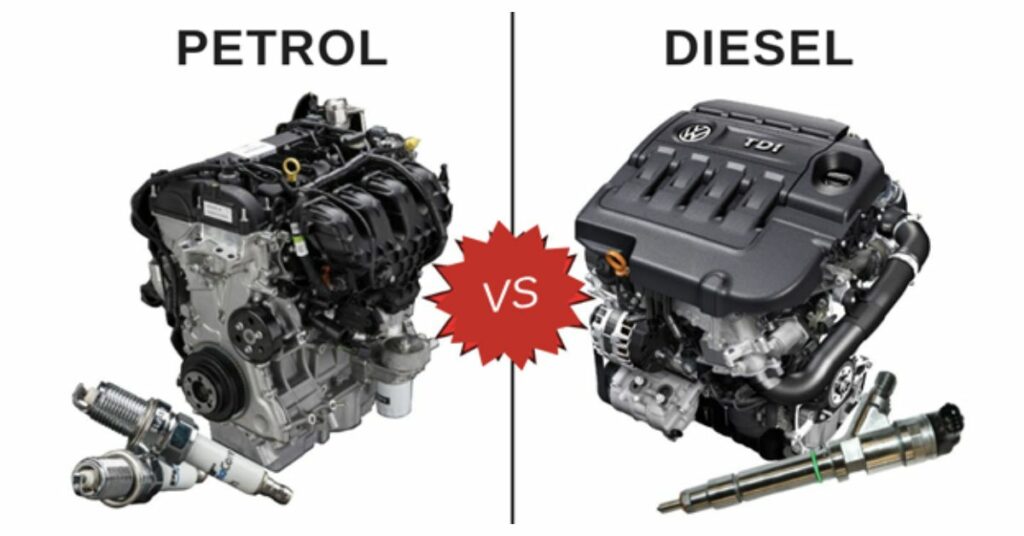

Thus, both types of engines use a succession of explosions to transform fuel into mechanical energy (combustions). Their primary distinction is how these combustions take place. Fuel is combined with air in gasoline engines before being compressed by pistons. Then sparks from the spark plugs ignite it. The air is compressed in diesel engines before it is combined with the fuel. Compressing the air causes it to heat up, which ignites the fuel.

You can learn all there is to know about diesel and gasoline engines in this comprehensive handbook.

INTERNAL COMBUSTION ENGINES’ PRINCIPALS PARTS

Theoretically, the fuel injection systems for gasoline and diesel vehicles are very similar. Chemical processes are converted into mechanical energy by these internal combustion engines. Moreover, both kinds of engines use pistons inside of cylinders to compress air and fuel prior to ignition.

The four-stroke combustion cycle—the intake stroke, the compression stroke, the combustion stroke, and the exhaust stroke—is used by diesel and gasoline engines alike. Read our most current post on the distinctions between two-stroke and four-stroke engines to find out more about each of these internal combustion engine operations.

Many systems that are essential to the performance of internal combustion engines are present. Let’s list the most significant ones first:

SYSTEM FOR FUEL INJECTION

Parts that work under low pressure and under high pressure make up a conventional fuel injection system. Its fuel tank, fuel delivery pump, and fuel filter are low-pressure parts. The high-pressure pump, a fuel injector, and an injector nozzle are examples of high-pressure components.

Until it is required to power the vehicle, fuel is kept in a fuel tank. The system’s low-pressure components arrive to the scene at that point. Fuel must be transferred from the tank to the fuel injection pump using the fuel supply pump.

The fuel injection pump is anticipated to apply high pressure and a precise amount of fuel to the injector.

A fuel injector then transfers the fuel from the fuel injection pump to the cylinders. Naturally, the nozzle—through which gasoline is injected into the cylinder—is one of the injector’s most important parts.

Cellulose or synthetic fibers are used to make fuel filters. They are responsible for reducing the danger of engine wear and poisoning by keeping water and debris out of the fuel injection system.

What are the main distinctions between the fuel systems for diesel and gasoline?

The way energy is produced in these two systems differs significantly. Before the fuel is introduced in diesel engines, the air is compressed. Gas and air are combined, compressed, and ignited in petrol engines.

Of course, the type of fuel utilized is another variation. Diesel evaporates more slowly than gasoline because it is heavier. It produces more hazardous nitrogen compounds while producing less CO2 and methane.

THE SYSTEM OF LUBRICATION

Many mechanical moving elements that make up an internal combustion engine necessitate constant lubrication. Crankshaft and connecting rod bearings, valve mechanisms, timing chains for the valves, the camshaft, and the space between the piston and the cylinder are a few of them.

This is the function of the lubrication system, which provides the appropriate amounts of engine oil to these parts. An oil pump, oil filters, an oil sump, an oil cooler, and an oil manifold are the main parts of a lubrication system.

Now, the oil tank contains a sump to supply adequate amounts of engine oil to all engine elements (oil pan). It is a representation of the lubricating system’s base. From there, oil is distributed either through the full pressure system or the splash system throughout the engine. Engine oil is kept free of impurities using oil filters.

Engine oil comprises a variety of cutting-edge additive packages that reduce wear and tear on the engine’s metal components by lubricating them and reducing friction between their moving parts. All of the engine oils in Valvoline’s product line are made with the best base oils and cutting-edge additive compositions. SynPower Premium, Max-Life High Mileage, and All Climate Year-Round engine oils are a few of our most well-liked engine oils. Having trouble deciding which is ideal for your diesel or gasoline vehicle? Speak with our Lubricant Adviser right away!

SYSTEM FOR COOLING

Your car’s internal combustion engine, whether it runs on gasoline or diesel, generates a lot of heat. Furthermore, if this heat is not efficiently dissipated, it could harm the engine and necessitate expensive repairs. Every internal combustion engine has a cooling system to address the issue.

Your engine’s cooling system serves a variety of purposes, including cooling combustion air, lubrication oil, and engine cylinders. A coolant pump, a radiator, a heat exchanger, a thermostat, and coolant filters are some of the parts that make up the cooling system.

The cooling system’s function is to allow the coolant to travel while adequately protecting engine parts from high temperatures. The coolant contains deterrent, anti-oxidation, and anti-corrosion characteristics in addition to guarding against freezing and overheating of the liquid. The coolant, also known as antifreeze, is made up of the right proportions of distilled water and coolant concentrate. Depending on the engine’s operating circumstances, it changes.

The coolant circulates repeatedly. It is forced throughout the engine via the water pump. The water jackets in the engine are the places where the coolant circulates to absorb the heat from the ICE. When the coolant gets too hot, the thermostat, a valve, directs it to the radiator. The thermostat regulates the coolant’s temperature. Via hoses, the hot fluid is introduced to the radiator, where it cools. A pump forces it from the radiator to the engine, and the cycle is repeated.

Inorganic (IATs) and organic coolants are distinguished by their chemical composition (OATs). Moreover, there are a number of combinations of these main coolant groups, including HOATs, P-HOATs, and Si-OATs. Each of these product categories has its own distinct characteristics and functions and makes use of a certain inhibitor technology. Because of this, it’s crucial to pick a product that is appropriate for your car’s cooling system. For motorbikes, heavy-duty trucks, recreational boats, and passenger automobiles, Valvoline has the broadest selection of cutting-edge cooling equipment.

ASSUMPTION SYSTEM

A device that lowers dangerous exhaust emissions from internal combustion engines is known as an aftertreatment system. It can be found in both gasoline and diesel engines. Via the exhaust, this system aids in removing extra combustion gas from the engine.

A particle filter, a catalytic converter, and a muffler make up a conventional diesel exhaust system. What you should know about each is listed below:

Diesel particulate filters (DPF) are used by diesel engines, while gasoline particulate filters are used by gasoline engines (GPF). Their primary function is to collect and get rid of exhaust soot.

- Carbon monoxide is converted into carbon dioxide using a three-way catalyst.

- Noise cancellation is achieved via a muffler

- Low SAPS lubricants, which have low levels of phosphorus and sulfur, must be used in automobiles with advanced aftertreatment systems. Discover lubricants that are TWC, DPF, and GPF compatible, like our Hybrid C2 5W-30 or SynPower MST C5 0W-20.

A TURBOCARRIIER

To increase the engine’s compression, the turbocharger pumps more air into the combustion chamber. More fuel can burn thanks to the higher air mass. It offers your engine a number of advantages, including improved performance, torque output, and fuel efficiency.

Original Equipment Manufacturers (OEMs) have the option of using mechanical or turbocharged superchargers today. The latter approach offers superior longevity and improved low-end performance. When it comes to compliance with tightly packed engine parts, it is more expensive and frequently a real challenge.

AN AFFILIATION

One of the most crucial components of your car is the transmission. Its primary function is to transform the mechanical power of the engine into wheel power. Both manual and automatic transmissions can be used, and both need different lubricants.

Planetary gears, clutches, brakes, a hydraulic pump, a transmission casing, and a torque converter make up the gearbox system.

The transmission fluid in your car can either be automatic or manual depending on the type of gearbox it has. Check out the range of gear and transmission fluids offered by Valvoline!

A SYSTEM OF ELECTRICITY

A starter motor, an alternator, and a battery make up the electrical system. To charge the battery, an alternator converts mechanical energy into electrical energy. A battery powers a starter motor, which converts electrical energy into mechanical energy to start the engine. In other words, once the crankshaft begins to turn, the pistons inside the cylinders begin to move. The air is compressed by the pistons to produce heat, which ignites the fuel.

ENTERPRISE CONTROL UNIT

Your car’s engine control unit (ECU) is in charge of ensuring optimal performance. For gasoline engines, it regulates the timing of the spark and the fuel injection. To ensure that the ignition system and injectors are turned on precisely when necessary, the ECU depends on the crankshaft position sensor.

PERCEPTION OF PETROL ENGINES

An example of an internal combustion engine is a gasoline engine. By burning gasoline that has been ignited by an electric spark, it produces power.

Gasoline engines come in a variety of types, and each type has multiple variants. Some of them include the way in which fuel is managed, rotor configuration, strokes per cycle, valve type, and others.

Piston-and-cylinder engines (which have sliding cylinders with closed heads) and rotary engines are the two fundamental types of gasoline engines (do not have traditional cylinders with back-and-forth moving pistons).

COMPREHENSION OF DIESEL ENGINES

A diesel engine bears Rudolf Diesel’s name, who created it. In 1893, the first diesel engine prototype was built, and it was initially powered by peanut oil.

This kind of engine burns fuel internally. This means that the energy in the diesel fuel is converted into rotary mechanical energy using compression ignition.

Diesel engines have compression-ignited systems as opposed to gasoline engines, which employ a spark-ignited system. In these systems, the engine’s combustion chamber receives the fuel injection. The mixture of air and diesel fuel is compressed by pistons in a diesel engine. This mixture erupts and forces the piston back up when the air is compressed, creating a reciprocating motion. The crankshaft of the engine further converts it to a rotary motion.

The presence of sophisticated aftertreatment systems in diesel engines is one of the main distinctions between them and their gasoline counterparts. Their job is to reduce particulate matter and transform harmful nitrogen oxide emissions into water and innocuous nitrogen. Simply said, they purify exhaust gases to lessen their negative effects on the environment.

Read More: